Timber & Wooden Signs

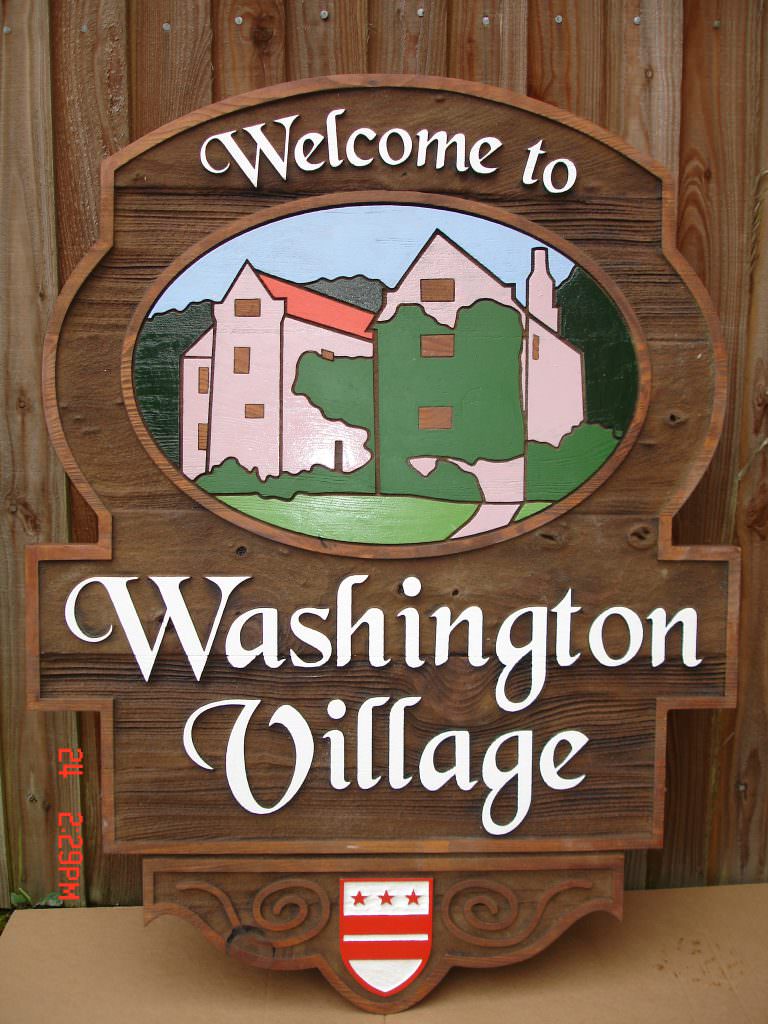

Timber and wooden signs can be supplied as individual panels, with some quite complex designs, or as part of a framing structure for a full-colour printed panel. The versatility of timber gives you scope for some highly individual graphics.

Most Wooden Sign projects start with us providing a quote. You can contact us via email, the enquiry form or give us a call – we are always happy to chat through your requirements.

Some clients know exactly what they want and provide a detailed brief. Other clients are looking for guidance and to explore options – we are happy to work with you to define your project.

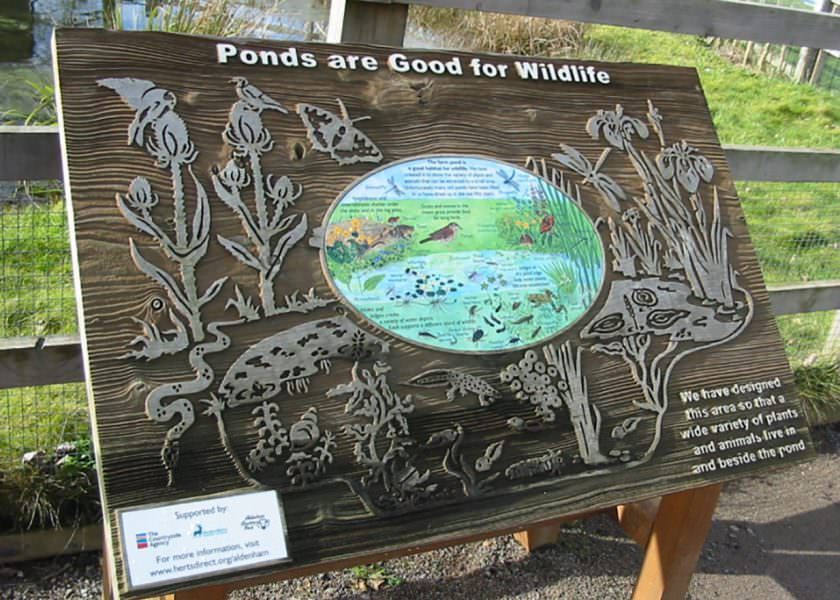

Timber & wooden signs are distinctive and individual and are good if you are looking to commission tactile, DDA-compliant signs for an external environment.

We can work with your graphic designers to produce your artwork, OR you can draw upon our in-house graphic design skills.

Remember, Remember… over time all wood signs, whether routed or sandblasted, will weather and may be subject to some movement. So, you are commissioning a timber sign that will turn into a ‘natural look’ on ageing, rather than opting for the long-term predictability of a GRP-encapsulated sign.

Here are some important considerations for wood and timber signs.

Graphic Design for timber & wooden signs

Our Shelley in-house design team are highly experienced at designing both routed and sandblasted custom wooden signs. Simple routed, or timber signs with indented graphics, are easy to design. However, the sandblasted option can be more complex. If you wish to use your own designers please make sure they speak to us at a very early stage of the project, as our requirements can be quite specific.

We are here to help … Please feel free to use our experience. We have a wide range of library wildlife illustrations you can use. We understand how to make tactile maps really work. We can advise how much text looks reasonable and fits into a given space. To discuss your requirements further, please phone Rob Shelley on Tel: 01952 541483.

Framing

Sandblasted timber signs are normally mounted on either vertical softwood posts or on lectern frames. Lectern frame-mounted wooden signs are often set at 60 degrees, to allow easy viewing by people in wheelchairs.

If timber signs or structures are being combined with printed GRP signs, there are numerous framing options available. The photos should give you some inspiration. Timber can be used as legs or lectern frames, or printed signs can be recessed into sandblasted wooden tops.

Content

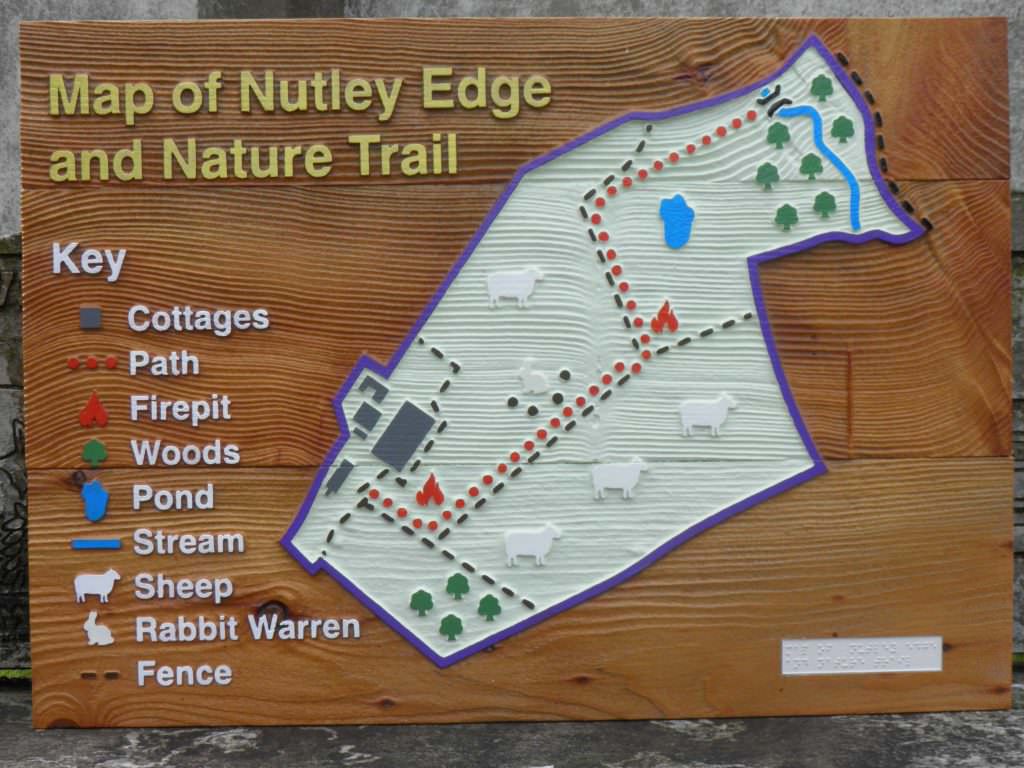

One of the hidden benefits of designing tactile sandblasted signs is that for effective production you are forced to follow good, interpretive design practice. Production techniques dictate that maps must be simple, text kept short, and illustrations fairly prominent. In addition:

- Directional and way-pointing signs can be as effective as routed timber

- Tactile information signs are best sandblasted. Keep your designs simple.

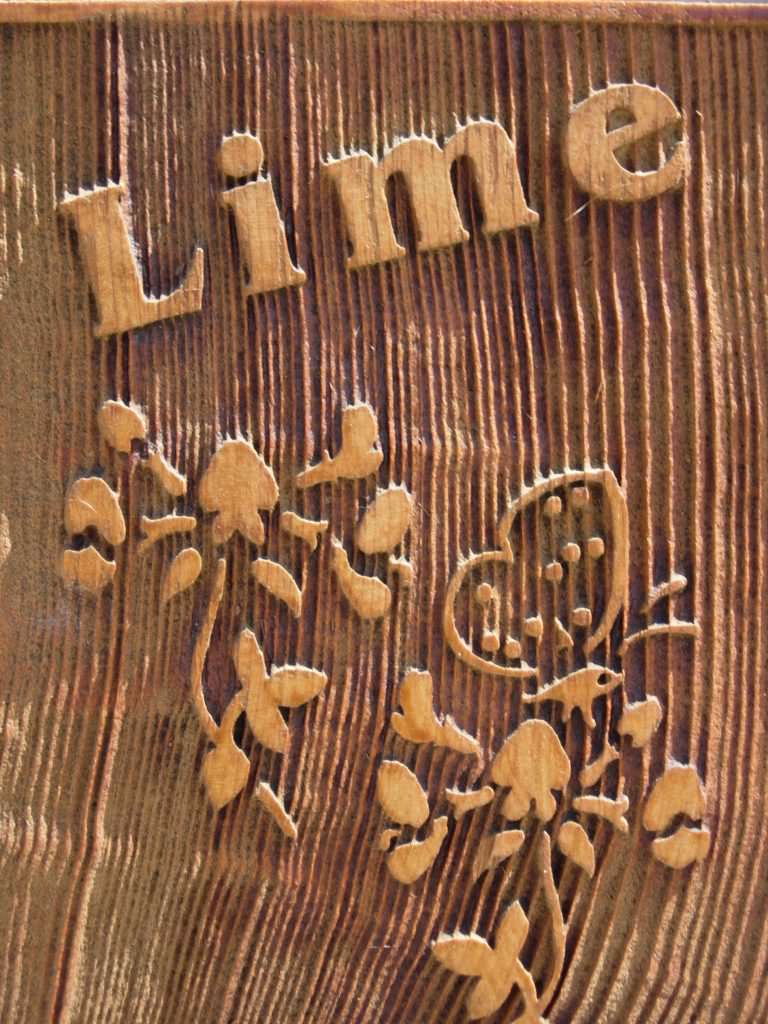

- The Shelley approach to sandblasted timber signs is to enhance the nature of the wood. We normally paint text and map details but leave illustrations unpainted, as silhouettes.

- We produce panels with a combination of tactile timber, Braille and printed full-colour plaques, but these can be a little too detailed. Think about your prospective audience and intended message even more carefully than normal when planning sandblasted signs.

Materials

We prefer to use sustainably sourced Cedar from the Stokesay Estate on the Shropshire–Herefordshire border for all our sandblasted, tactile timber signs. We know from experience that this wood sandblasts beautifully and reliably, is locally-sourced and is part of the sustainable management of the estate [although not FSC]. Timbers from FSC sources are available if you prefer but, from our experience, they do not always sandblast as well and are sometimes imported.

Timber & Wood signs Summary

Shelley Signs are specialist suppliers of a range of routed and sandblasted timber, wooden signs, and directional signs and information signs for public open spaces. We can get involved at whatever stage of your project that you want. We can supply you a design, print your own graphics, and build your frames and structures – all of which are done in-house at our Shropshire factory, which you are welcome to visit to assess our capabilities.

Directional Signs

Directional wood signs such as finger posts are suitable for wayfinding in parks, nature reserves, public open spaces and urban environments. Wooden finger posters are available in oak or pressure-treated softwood. Our preference is to use durable wood such as oak that will highlight the natural beauty of the wood sign and over time will give a rustic appearance.

Wayfinding

Wooden wayfinding signs and Interpretation boards are a classic way to provide directions and information to visitors about the environment around them and can cover both natural history and archaeological themes. We specialise in the production of wood signs and panels for nature reserves, public open spaces and visitor attractions.

Bollards

Bollards are wooden signposts that are normally produced in either oak or top quality, pressure-treated softwood to ensure longer life. While bollards can be used to control traffic flow in a park environment they offer a discreet way to direct visitors and can include waymarker discs or routed images.

Wooden Signs & Notice Boards

A high-quality wooden sign can add an air of sophistication and style. In parks or open spaces wooden signs fit perfectly with the natural environment. We design, manufacture and install bespoke wooden signs for a variety of organisations.

Available as wall-mounted, floor-standing, or fixed displays, our custom wooden signs are also available with the addition of a notice board, a common feature found in parks, churches and nature reserves.

Frequently Asked Questions

There are a variety of woods that can be used for signs, but the most common and sustainable durable timber is red cedar. Cedar is a durable wood that sandblasts well, making it ideal for tactile signs. It is also locally sourced in many areas, which reduces the carbon footprint of the sign. Other options for wooden signs include oak, maple, and cherry.

The size of the wooden sign will depend on the intended use and location. For directional signs, it is important to make the sign large enough to be easily seen and read from a distance. Information signs such as interpretation boards can be smaller, but should still be readable from a few feet away.

Wooden signs are made using a variety of methods depending on the type of sign. Routed signs are made by carving the design into the wood, while sandblasted signs are made by using a high-pressure stream of sand to carve the design. Both methods can be used to create a variety of effects, from simple text to complex illustrations.

Routed wood signs are great for creating individual and distinctive signs for visitor attractions and commercial properties. These are manufactured on CNC routers and usually have indented graphics. Shelley Signs produced routed signs in a variety of woods including oak, Douglas Fir, Larch, pressure-treated softwood and Iroko. We also produce routed signs in recycled plastic, HDU sign foam, foamex and a wide range of PVCs.

Sandblasted wooden signs are created by removing layers of material, producing signs with raised tactile graphics. Sandblasted signs can be produced individually or can be incorporated with full-colour printed graphics to provide additional flexibility. At Shelley Signs we believe in really enhancing the sign by exposing the beautiful grain of the wood, so we advise against choosing a fully painted wooden sign. Our preferred approach is to paint text and map details but to leave all illustrations unpainted, as silhouettes. If wooden signs are heavily painted the attractive features of the wood become masked.

Wooden signs can last for many years with proper care and maintenance. Routine cleaning with soap and water is usually all that is needed to keep the sign looking its best. If the sign is located in a high-traffic area, it may need to be refinished every few years to maintain its appearance.

A wooden sign has a number of advantages over other types of signs. They are environmentally friendly, durable, and have a classic look that can enhance the appearance of any business or public space.

Routed Timber Signs

Timber signs offer a great opportunity to create individual and distinctive signs for visitor attractions and more commercial properties.

Sandblasted Timber Signs

While our routed or indented signs offer an interesting and distinct sign or graphics solution the flexibility and appearance of the sandblasting process goes a step further.